Agronomic Row Crops

Flex-Tine Weeder

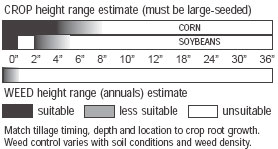

Overview: Spring wire tines scratch the soil surface to uproot tiny weed seedlings. Up to 25 tines per toolbar foot are mounted in a staggered fashion on three or six mounting bars, resembling the layout of a spike-tooth harrow. The bent tines vibrate rapidly and glide around or over obstructions. A tine weeder works in loose or lightly crusted soil with no long-stemmed residue. When used postemergence, crops must be well-rooted. Excellent within its limits for high speed, preemergence and early postemergence broadcast weeding. Stiffer tines break through heavier crusts but lose some of their vibrating action.

Design Features: Coiled-loop or other spring mounting may allow five to nine position tension adjustment. This tensioning, tine diameter selection (sized 6mm to 8mm, or about 3/16 " to 1/4"), three-point hitch height and gauge wheel setting combine to determine degree of soil penetration. Many makers allow individual tines to be raised up over crop rows while other tines are down for inter-row, postemergence cultivation. Well suited for cultivation of hilled crops such as potatoes, as tines can be adjusted to follow contour of field. There are many brands of weeders in Europe, where the tools are often used in small grains or to incorporate cover-crop seed. Frame clearance of 14" to 18" varies with tine length.

Model for comparison: 10' wide, or maker's smallest model

Rec. PTO HP: 30 Speed: 4 to 8 mph

List price: $1,800 to $2,940

Width range (all makers/all models): 50" to 45'

Larger models, 30' to 45', overall average $6,600

Sources: 39, 48, 53

Farmers: Chambers, deWilde, Haines, Reeder