Once you have decided to market your own beef, it won’t take long before you figure out that things would be easier if your marketing effort were bigger. That’s because conventional beef marketing is set up to move huge quantities of beef very cheaply. Unfortunately, there are a lot of people who have lost an awful lot of money trying to do this.

Large beef processing and distribution companies can move huge quantities of meat very cheaply because they’ve been at it awhile. Although we dislike the dominating corporate nature of their business, we have a great deal of respect for what they have been able to accomplish. They do what they do very well.

When we first started out, we made a presentation to a very kind individual with a natural foods distribution company. He informed us that we were not experienced enough or large enough to service them properly. He also suggested that we sell directly to our area’s small natural food buying clubs, which were his customers. Even though we were a trifle (okay, maybe a lot) peeved at his suggestion, it turned out to be some of the best advice we have gotten.

We learned what cuts the customers want, how they want it packaged, and how many pounds to put in each package – as well as a myriad of other details we hadn’t even thought about. For example, we found out that customers liked beef in see-through fresh food packages better than if it was wrapped in butcher paper, because they could see the meat.

Moreover, we found out that our customers like 1-pound packages of ground beef more than 2-pound packages (2 pounds was too much for most families).

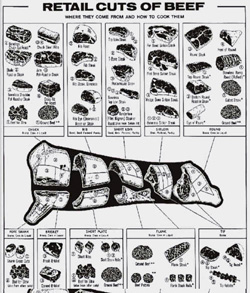

These basic industry definitions help you sound like you know what you’re talking about, although you don’t really need to know them.

|

If you are just starting out, sell to your friends or to groups. Sell sides of beef using an ad in the local paper. Call up local groups – like the Elks – and ask if you can sell them the beef for their next big barbecue. Invite comments and criticism. You need all these experiences.

If people criticize your beef – rightly or wrongly – the natural thing to do is defend yourself. Try not to. It will only create ill will between you and your customers. Just be gracious and thank them for their comments. Offer their money back.

When first starting out, you will need to restrain yourself from being big. Start small and stay small until you have worked your way through all the surprises. Then take on some more demand. Do it incrementally, do it slowly. No one gets everything right. There are too many things to go wrong. The mistake that gets you won’t be one you know, it’ll be one you hadn’t even considered. Your margins won’t be as big when you are small. By the same token, a mistake won’t kill you either. Take it slow, work your way through mistakes, and be creative. There is always more than one way to skin a cat.

Don’t buy a refrigerated truck. Don’t buy any processing equipment. Don’t buy a processing facility. Lease or hire it until you are a few years down the road.

Jim Goodman of Wonewoc, Wis., bought a walk-in freezer as his only initial start-up equipment. He says his business would have been impossible without it. “It allows us to sell on the farm, makes getting ready for the farmers market, where all meat must be sold frozen, quick and easy, with no running to rented freezer sites,” he says.