Horticultural Crops

Finger Weeder

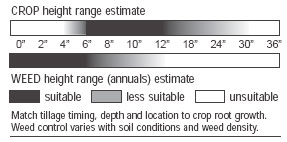

Overview: Steel cone wheels - rotated by ground-driven spike tines - push rubber 'fingers' just below the soil surface, reaching into the row. Fingers can work safely in the row in crops that have sufficient stem strength and root resistance, such as corn, strawberries, nursery stock. Tool dislodges small weeds (up to 1") only; operating depth 0.5" to 0.75". Works best in loose soils, and will not work in heavily crusted soils or where long stemmed residue is present. Usually 'belly mounted' under motor block, but can be mounted on three-point rear hitch, or on outriggers for split-row coverage in nursery use.

Two pairs of finger cone wheels run in sequence, followed by a pair of bent-tine mulching cone wheels. The finger wheels tilt downward so that the rubber fingers hit the soil at an oblique angle. Set the leading finger wheels about 1" further apart than the rear ones. On stiff-stemmed crops, the second set can be positioned to have fingers overlap one-half inch for total in-row coverage. More tender plants need greater distance to prevent crop damage. Multiple row units require 36" between rows.

Design Features: Eighteen flexible rubber fingers 3.5" long radiate from 7" metal hubs. Angle and adjustment determine aggressiveness of action. Springs cushion impact by obstructions. Rigid frame requires level bed for best results.

Model for comparison: one-row, two sets of finger cones, one set mulching cones.

Rec. PTO HP: 25

Speed: 3 to 6 mph

List price: $1,180 to $1,500

Width range (all makers/all models): 1 to 2 rows

Sources: 15, 53

Farmers: Harlow, Muller