Details on composting processes and methods are outside the scope of this article but are presented elsewhere in comprehensive manuals [3]. Two of the most important factors for successful in-house composting are the appropriate C:N ratio and moisture content of the material. Carbon to nitrogen ratio should be in the range of 20:1 to 40:1, with moisture contents in the range of 40 to 65% by weight. Practitioners are encouraged to purchase a comprehensive reference on composting methods, and to periodically have samples of material analyzed to compare results to desired ranges and make adjustments as necessary.

Carbon requirements

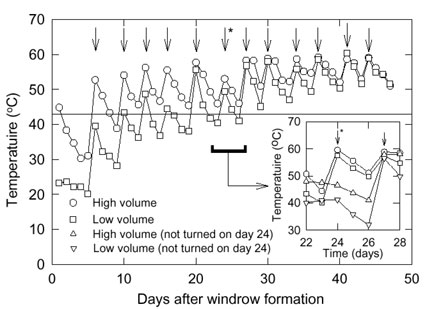

Initial research showed that high composting temperatures could be achieved in-house using relatively low rates of carbon material (200 to 600 lbs per 1,000 square feet of floor area, [4,5]) (Figure 2). The resulting C:N ratio of the compost, however, was approximately 10:1, much lower than recommended for optimum composting. Composting with a low C:N ratio contributes to high rates of ammonia gas evolution and atmospheric ammonia concentrations inside the layer facility. While using less carbon extends the length of time compost can accumulate before the volume exceeds the capacity of the turner, the resulting high rates of ammonia volatilization are not sustainable from an air quality perspective.

Increasing the amount of carbon used to produce a target C:N ratio of 20:1 to 40:1 will reduce ammonia volatilization. Formulae are available to calculate the exact amount of carbon necessary to achieve a target C:N ratio, knowing the characteristics of the manure and carbon source material [3]. Higher C:N ratio carbon sources are desirable, as they reduce the total amount of carbon required. Depending on the source, from 1/3 to 2 pounds of carbon per pound of manure would be required for an optimum C:N ratio with in-house composting.

According to published research, a single laying hen produces approximately 0.058 lb manure per day (41% moisture equivalent) [6]. The C:N ratio of layer manure averages 8.5 [4,5]. Using this information, together with data on the carbon source and the formulae cited above, the total amount of carbon needed for a given number of birds and length of time composting will occur can be calculated. Research [1] also suggests that as much as 35% of the manure decomposes during in-house composting, so some adjustment in the amount of manure may be warranted when forecasting carbon requirements.

Since manure is added continuously over time, all of the carbon should not be added at the beginning of an in-house composting cycle. Divide the carbon into three or more separate applications made at regular intervals during a cycle. For example, in a six-week cycle, add approximately 33% of the carbon at the beginning of the cycle, 33% after two weeks, and the final 33% after four weeks.